Specifics of modernization projects at existing facilities

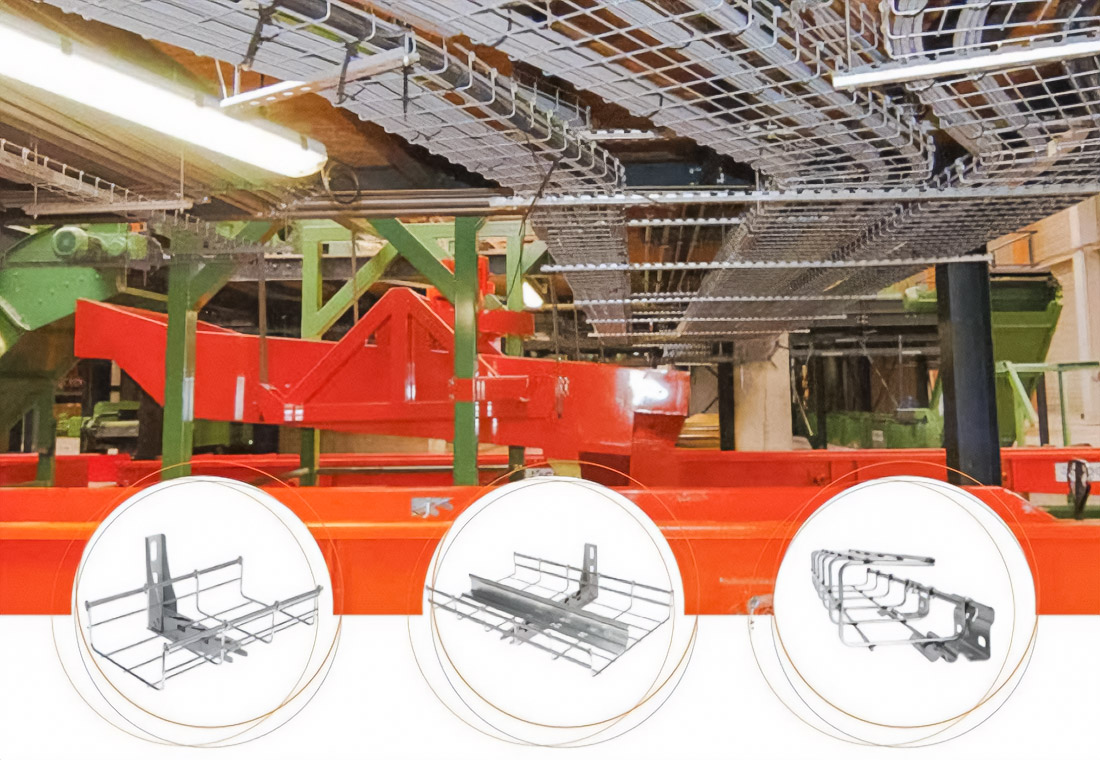

Industrial enterprises often work non-stop 24/7. Retrofit projects include replacing cable routes in conditions of limited space, maintaining safety and power supply. This requires flexibility in logistics, precise size matching, and ergonomic products that can be easily integrated into existing infrastructure.

2. Technical requirements for cable trays

- Bearing capacity: performance of trays is specified against maximum loads (up to 75 kg/m) and span (up to 2 m) to ensure trouble-free operation in the presence of vibration and thermal Deformation.

- Materials and coatings: depending on the application conditions, preferential use is made of stainless steel, hot-dip galvanizing (ISO 1461), and epoxy coatings.

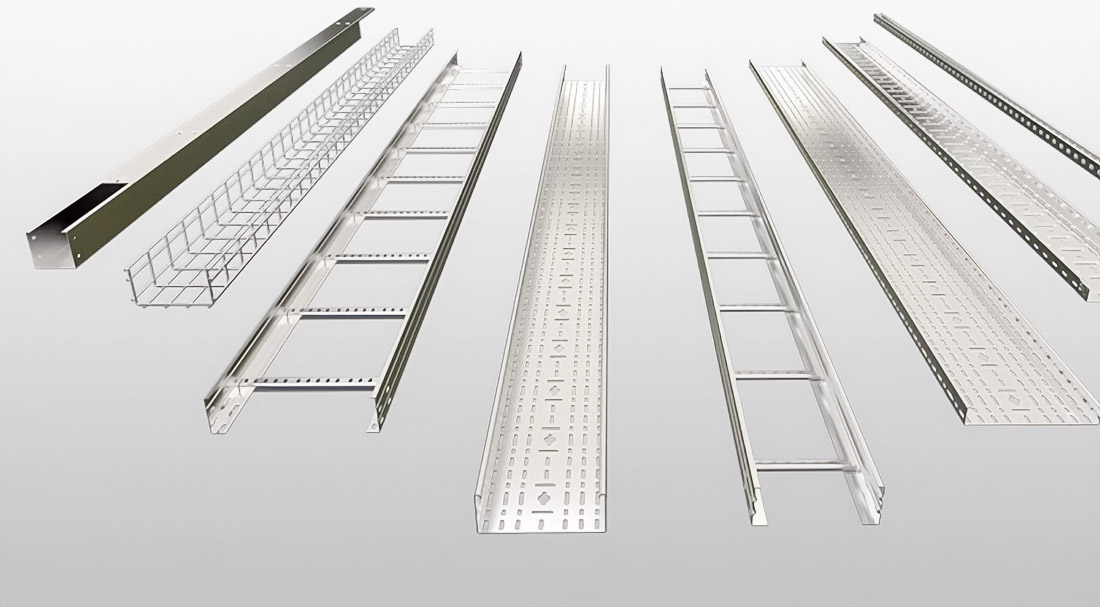

- Construction type: ladder and perforated trays for good ventilation and cable access in constricted space.

3. Key criteria for choosing a supplier

- Warehouses in the UAE: local availability of products speeds up delivery and offers flexibility in reacting to urgent modernization requests.

- Compliance: the supplier has to comply with BS EN 61537 for mechanical loads and ISO 9001 for quality stability.

- Customization: any non-standard solutions, e.g., angular transitions, branching, adaptation to the peculiarities of the object.

- On-site support: Engineering support during purchase and installation, technical drawings, compatibility with existing equipment.

4. Overview of the practices of cable tray suppliers in the UAE

Some companies specialize in providing solutions specifically for industrial facilities:

One of the leading cable tray suppliers in UAE focuses on projects at existing industrial facilities where high reliability with continuous operation is required. They offer ready‑made solutions for retrofit work, including quick-to-assemble structures and accessories that minimize installation time.

Another supplier provides a full range of cable systems: ladder, perforated, wire and heavy-duty trays. Special attention is paid to adapting to the typical sizes of pipes and cable passages at existing facilities, as well as complying with the coating according to ISO 1461 and BS EN 61537 standards.

5. Advantages of coastal and industrial solutions

In case of corrosive conditions in coastal and technological zones, they are important:

- reducing downtime by installing products with a long service life and minimal maintenance.

- reducing track replacement and maintenance costs.

- the possibility of using hot dip galvanizing according to ISO 1461 and other coatings resistant to aggressive environments.

Results

Retrofit projects at existing industrial facilities in the UAE have special requirements for durability, corrosion resistance and logistics.

Cable tray suppliers in UAE offer solutions with a high level of adaptability, compliance with international standards and stocks in the country.

The main selection criteria are compliance with BS EN 61537 and ISO 1461, prompt delivery, support and the possibility of customization to meet the requirements of the project.

Such suppliers help to quickly modernize cable routes without stopping production and with minimal delays.

Cyclist, doer, hiphop head, Vignelli fan and storyteller. Operating at the junction of modernism and programing to create strong, lasting and remarkable design. I sometimes make random things with friends.